Let me introduce SMG TGS's products.

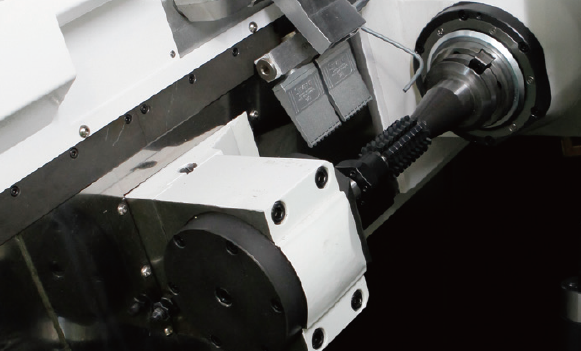

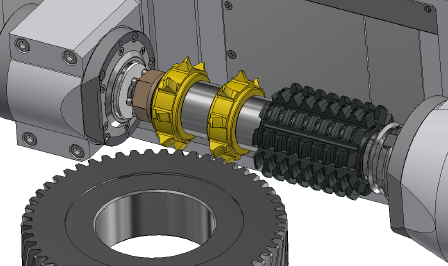

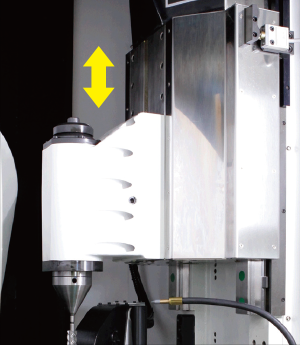

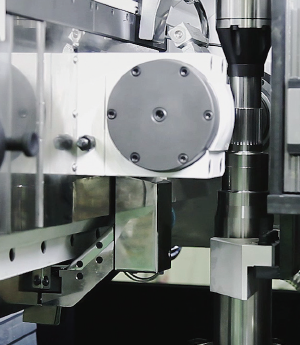

Realization of Zero Backlash by applying High torque Direct-Drive Motor on C-axis

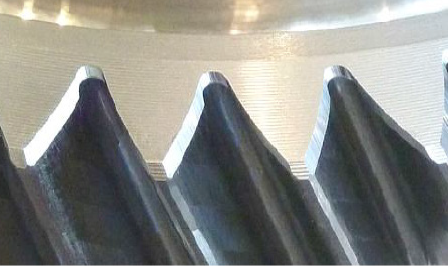

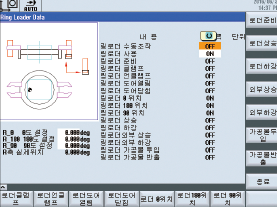

Wet and Dry hobbing process on the same Machine

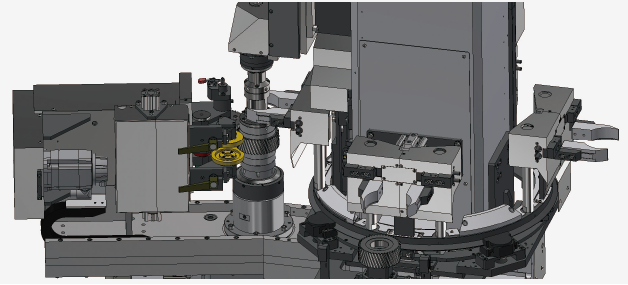

High speed and High reliability Ring loader enables a variety of automation

Optimized Dry cutting system & Thermal Stability

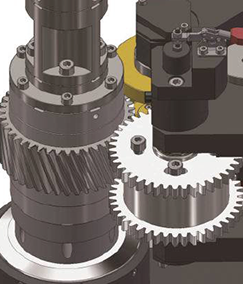

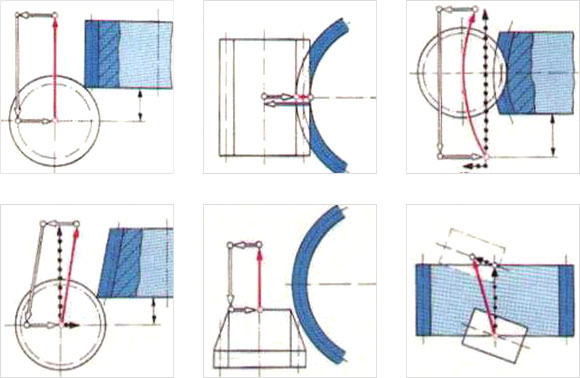

Optimized Stucture by Structural Analysis(FEM)

High Accuracy(Above DIN 6 Grade)

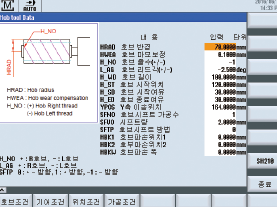

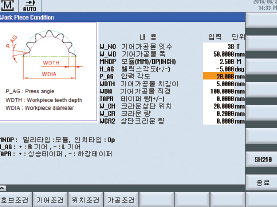

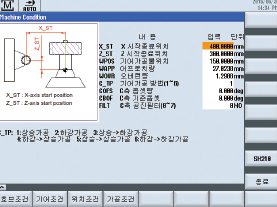

User Friendly Siemens 840D SL / 828D & Easy Dialogue P/G

<SH210>

<SH210>

<SH410>

<SH410>

| Model | SH210 | SH260 | SH310 | SH410 |

|---|---|---|---|---|

| Machine Capacity | ||||

| MAX. Workpiece Dia. (Automation) |

Φ210mm | Φ260mm | Φ310mm | Φ410mm |

| Max. Workpiece Dia. (Manual) |

Φ350mm | Φ350mm | Φ350mm | Φ410mm |

| Max. Module | M6 | M6 | M6 | M8 |

| Max. Table Speed | 300rpm | 300rpm | 300rpm | 200rpm |

| Table Dia. | Φ240mm | Φ240mm | Φ240mm | Φ330mm |

| Base Jig Dia. | Φ130mm | Φ170mm | Φ210mm | Φ260mm |

| Hob Head | ||||

| Max. Hob Dia. Length | Φ180/220mm | Φ180/220mm | Φ190/230mm | Φ190/230mm |

| Max. Hob Speed | 2000rpm (Opt.1000,1500rpm) |

2000rpm (Opt.1000,1500rpm) |

1500rpm (Opt.1000,2000rpm) |

1000rpm (Opt.1500,2000rpm) |

| Max. Hob Shift(Y·axis)Travel | 200mm | 200mm | 210mm | 210mm |

| Hob Swivel Angle | ±45˚ | ±45˚ | ±45˚ | ±45˚ |

| Hob Arbor Taper | BBT #40 | BBT #40 | BBT #40 | BBT #40 |

| Hob Spindle Output | 12 kW | 12 kW | 12 kW | 15 kW |

| Working Range | ||||

| X-axis Travel (Radial) | 270(15~285)mm | 270(15~285)mm | 270(15~285)mm | 290(15~305)mm |

| Z-axis Travel (Axial) | 370(200~570)mm (Opt.600(200~800)mm) |

370(200~570)mm (Opt.600(200~800)mm) |

370(200~570)mm (Opt.600(200~800)mm) |

370(150~520)mm (Opt.600(150~750)mm) |

| Tail stock Center Travel | 400(355~755)mm | 400(355~755)mm | 400(355~755)mm | 400(305~705)mm |

| Rapid | ||||

| X-axis Rapid (Radial) | 12m/min | 12m/min | 12m/min | 12m/min |

| Z-axis Rapid (Axial) | 12m/min | 12m/min | 12m/min | 12m/min |

| Y-axis Rapid (Tangential) | 5m/min | 5m/min | 5m/min | 5m/min |

| Other Specification | ||||

| Number of Axes | 6(X,Y,Z,A,B,C) | 6(X,Y,Z,A,B,C) | 6(X,Y,Z,A,B,C) | 6(X,Y,Z,A,B,C) |

| CNC Control System | Siemens 840D SL | Siemens 840D SL | Siemens 840D SL | Siemens 840D SL |

| Full splash guard type Floor Space (L*W*H) |

Close top 2741*3238*2970mm |

Open top 2741*3238*2970mm |

Open top 2741*3238*2990mm |

Open top 2776*3329*2990mm |

| Machine Weight | 9500kg | 9500kg | 9500kg | 11000kg |

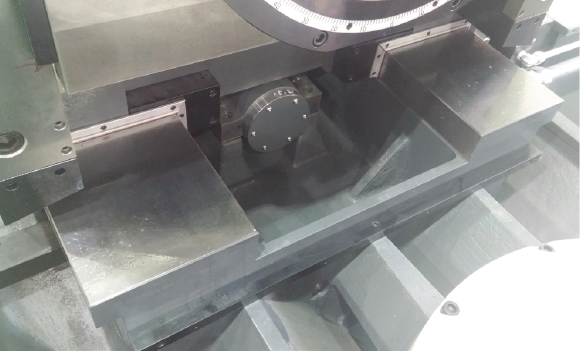

<X-axis Slide Way>

<X-axis Slide Way>

<Z-axis Slide Way>

<Z-axis Slide Way>

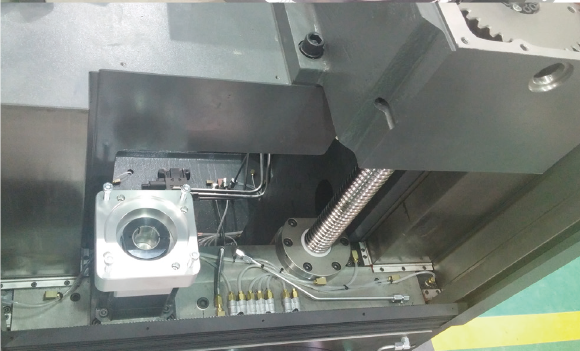

This machine is Designed for Wet or Dry Cutting

Slope type bed provide the best Chip disposal condition

High pressure air nozzle and SUS guard on the bed provide Optimized Dry cutting system and High Thermal stability

<High pressure air nozzle

<High pressure air nozzle  <Inner SUS guard>

<Inner SUS guard>

<4-Station Ring Loader

<4-Station Ring Loader <After Chamfering/Deburing>

<After Chamfering/Deburing>

<Stocker Conveyor>

<Stocker Conveyor>

Various processed goods can be attached.

<Gantry & Stocker>

<Gantry & Stocker>

<In/Out Stocker>

<In/Out Stocker>

Various automation of customer specifications is possible. (Robot, Gantry, Automation Line of customer specifications)

<Robot Automation>

<Robot Automation>

<Customized

<Customized  Automation

Automation

Automation

Automation

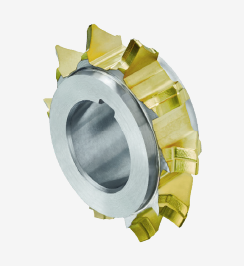

Skiving(without ringloader)

Skiving(without ringloader)

Skiving(with ringloader)

Skiving(with ringloader)

Pre-Deburring unit

Pre-Deburring unit

Coolant Oil Coolder

Coolant Oil Coolder

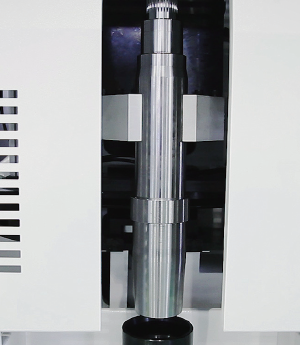

Hob Arbor

Hob Arbor

Steady Rest

Steady Rest